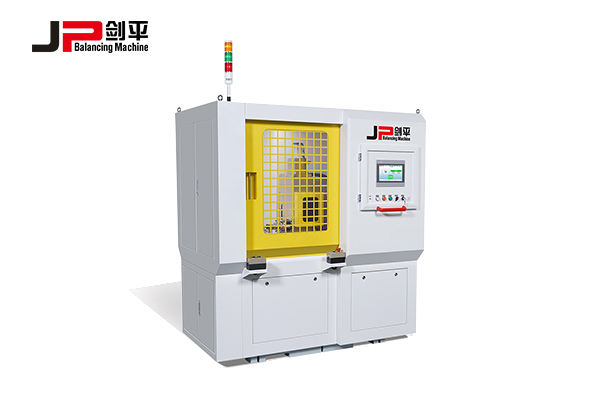

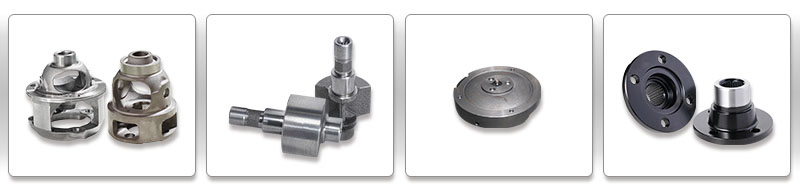

Vertical radial drill automatic balancing machine is used in the auto parts industry, such as flywheels, flanges, eccentric shafts, pump housings, differential cases, etc., which require cross-sectional weight removal rotor dynamic balancing processing.

Application industry of this balancing machine

Features:

1.10 inch touch screen

2. Advanced unbalance measurement software technology

3. Automatic measurement, automatic drilling & correction, automatic retest

4. Reasonable structure design, high machine efficiency

5. The workpiece can be corrected more than twice

6. Manual loading & unloading

Function of this vertical radial drilling automatic balancing machine:

An unbalanced rotor generates a pressure on its supporting structure and the rotor itself during its rotation, and causes vibration. Therefore, the balancing of the rotor is very necessary. The balancing machine is to check the dynamic unbalance of the rotor in the rotating state, and the function of dynamic balancing is

Improve the quality of the rotor and its components

Reduce noise

Reduce vibration

Extend the service life of supporting parts (bearings)

Reduce user discomfort and reduce product consumption

In the daily operation and use of the vertical radial drilling automatic balancing machine, some minor problems occasionally occur. Some problems are caused by the workpiece itself, and some problems are caused by the balancing machine itself. These problems might affect the balancing accuracy, or even cause the balancing machine to fail to complete the work normally. So what will affect the work of the fully automatic balancing machine? How can we solve these problems?

Factors that cause the balancing machine to not work properly

1.The influence of the workpiece itself

When the balancing accuracy cannot meet the balancing requirements of the workpiece

When the roundness of the support of the workpiece itself is not good

When the rigidity of the workpiece itself is not good

When the actual working status of the workpiece is inconsistent with the unbalance correction status.

2.The influence of the balancing machine itself

The foundation on which the balancing machine is installed does not meet the requirements and is likely to cause resonance

The left and right supports are not on the same horizontal line, which will easily cause the rotor to move from side to side

Sensor output signal is abnormal

The photoelectric head of the balancer is not aligned with the reflective paper, which may cause the angle to offset.

There are many situations in which the balancing machine cannot work normally due to the problem of the workpiece itself and the reason of the balancing machine itself. Therefore, when purchasing a vertical radial drilling automatic balancing machine, the details of the workpiece must be clearly described. The machine needs to be fully debugged before the automatic balancing machine is put into use.

Common faults and simple handling methods of balancing machines

1.Fault 1: The displayed value has a large error. Display value error includes angle error and amplitude error

Handling method: check whether the rotor itself is qualified; whether the balancing speed is stable; the output of the sensor; re-calibration

2.Fault 2: No speed or excessive change in display speed

Handling method: adjust the distance between the phase detector and the reflective paper properly, and the distance between the emitted and received light of different phase detectors is different

3. Fault 3: It shows that the measurement data is very small or even wrong, no matter how you add the balance weight, there will be no obvious change

Handling method: adjust the sensor resistance or adjust and replace the sensor; check whether the connection between the sensor output terminal and the electronic measuring unit is connected; check the self-checking function of the electronic measuring unit

Of course, the construction and structure of the balancing machine are more complicated, and other problems will certainly arise. If you have other questions related to the vertical radial drilling automatic balancing machine, you can consult the manufacturer of the dynamic balancing machine manufacturer - Shanghai Jianping. No matter what, we hope everyone can pay attention to the precautions when using the vertical radial drilling automatic balancing machine to prevent unnecessary damage.

.png)

.png)

.png)