The advancement of science and technology has brought many challenges and opportunities, and dynamic balancing machines are no exception. Let's take a look at the molecular pump dynamic balancing machine. Before we learn the molecular pump dynamic balancing machine, let us first understand what is a molecular pump?

The molecular pump is an oil-free high vacuum pump. The molecular pumps are mainly divided into turbo molecular pumps, compound molecular pumps, and magnetic levitation molecular pumps.

Working principle of molecular pump

The pumping mechanism of molecular pumps is different from that of mechanical pumps that pumping by changes in the volume of the pump chamber. The principle of momentum transfer is used to make molecules flow in a directional direction and be discharged out of the pump to achieve the purpose of pumping.

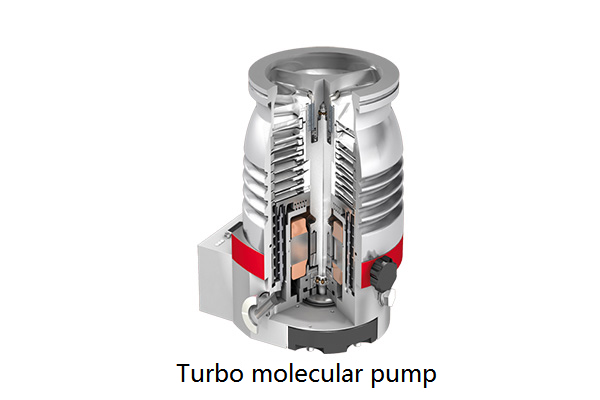

The molecular pump rotates at a high speed under the drive of a motor, and the motor is driven by a variable frequency power supply in order to obtain a higher speed. In the molecular flow area, the gas molecules collide with the surface of the blade that rotates at high speed, and the momentum is transferred to the gas molecules, so that some of the gas molecules produce directional flow in the direction of movement of the rigid body surface and are discharged out of the pump to achieve the purpose of pumping. Generally, the phenomenon that the surface of a rigid body that moves at a high speed carries gas molecules and makes them move in a certain direction is called molecular traction. Vacuum pumps made using this phenomenon are called traction molecular pumps(Gade pumps). The advantage of the traction molecular pump is that it has a short start-up time and a high compression ratio in the molecular flow state. It can pump out various gases and vapors, and is especially suitable for pumping out heavier gases. However, due to the low pumping speed of the traction molecular pump, the too small sealing gap, poor working reliability, easy mechanical failure, and difficulty in manufacturing, it is rarely used in practice. Later, the traction molecular pump was improved, and a turbo molecular pump appeared, as shown in the figure below

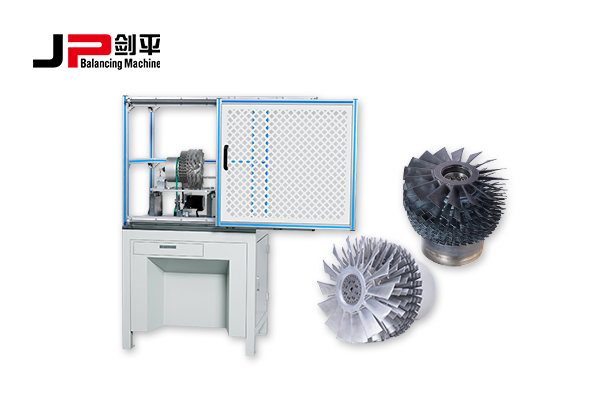

The compound molecular pump is a series combination of a turbo molecular pump and a traction molecular pump. It combines the advantages of the two pumps. It can be in a wide pressure range of 10-6~1pa, with a larger pumping speed and a higher compression ratio, which greatly increases the outlet pressure of the pump. For the special rotors of molecular pumps, Shanghai Jianping carried out dynamic unbalance test for them, and designed a special balancing machine equipment for the dynamic unbalance detection of molecular pumps based on the characteristics of molecular pumps.

The molecular pump rotates at a high speed under the drive of a motor, and the motor is driven by a variable frequency power supply in order to obtain a higher speed. In the molecular flow area, the gas molecules collide with the surface of the blade that rotates at high speed, and the momentum is transferred to the gas molecules, so that some of the gas molecules produce directional flow in the direction of movement of the rigid body surface and are discharged out of the pump to achieve the purpose of pumping. Generally, the phenomenon that the surface of a rigid body that moves at a high speed carries gas molecules and makes them move in a certain direction is called molecular traction. Vacuum pumps made using this phenomenon are called traction molecular pumps(Gade pumps). The advantage of the traction molecular pump is that it has a short start-up time and a high compression ratio in the molecular flow state. It can pump out various gases and vapors, and is especially suitable for pumping out heavier gases. However, due to the low pumping speed of the traction molecular pump, the too small sealing gap, poor working reliability, easy mechanical failure, and difficulty in manufacturing, it is rarely used in practice. Later, the traction molecular pump was improved, and a turbo molecular pump appeared, as shown in the figure below

The compound molecular pump is a series combination of a turbo molecular pump and a traction molecular pump. It combines the advantages of the two pumps. It can be in a wide pressure range of 10-6~1pa, with a larger pumping speed and a higher compression ratio, which greatly increases the outlet pressure of the pump. For the special rotors of molecular pumps, Shanghai Jianping carried out dynamic unbalance test for them, and designed a special balancing machine equipment for the dynamic unbalance detection of molecular pumps based on the characteristics of molecular pumps.

Scope of application

It is suitable for the dynamic unbalance detection of molecular pump.

Features:

1. Convenient for the loading & unloading of workpiece

2. Soft -bearing bracket system designed by Jianping

3. Modular design, applied to the balancing of molecular pump impeller

.png)

.png)

.png)