Crankshaft balancing machine to improve the generator crankshaft balance

Article Source: Jp Balancing Machines

Time:2018-01-03

Now that the family car has entered the door of every family, followed by a variety of car problems plagued by the driver often have to ask: Why open the same mileage, my car engine noise so much , Loss so serious? In fact, this is because we did not pay attention to the engine care and maintenance, which led to crankshaft failure

Crankshaft introduction

The crankshaft is the most important part of an engine that takes the force from the connecting rod and converts it into torque that is output through the crankshaft and drives the other attachments to the engine. Crankshaft requires sufficient strength and stiffness, journal surface wear-resistant, uniform work, good balance.

Crankshaft fault reason

(1) long-term overload work. Overloading causes the crankshaft to fatigue for a prolonged period of time, and crankshafts may crack or break due to excessive torque if the vehicle or equipment is operated slowly due to overloading (such as long-term overloading) .

(2) After the start of large-load high-speed operation. At this point, the original crankshaft at rest, due to the role of gravity, the crankshaft close to the bearing, there is no oil film. If high speed operation immediately after start-up, oil film can not be formed immediately due to lag of oil, crankshaftand bearing bush may be "burned" due to dry friction and lead to abnormal damage of the crankshaft.

(3) poor quality oil. Oil viscosity is too low or oil quality level is insufficient, will lead to oil pressure is too low and can not form an effective oil film, the journal and the bearing may also produce dry friction between the same and lead to the burning of tile-bearing failure.

(4) the balance of the crankshaft itself poor performance

Therefore, to extend the service life of our car, there is a comfortable driving environment, on the one hand to learn the engine maintenance, maintenance, on the other hand to use the crankshaft balancing machine .

How to improve engine crankshaft balance?

Ferrari and many European super-run are using a flat crankshaft V8 engine, the sound waves strong and powerful dynamic response so that sports car enthusiasts mesmerized, although the plane crankshaft can provide a very good engine response, will launch a beastly general Roar, but the engine with a flat crankshaft has a physical headache that's annoying - that's annoying vibrations. Although we can not eliminate the vibration, we can minimize the vibration through the calibration of crankshaft automatic balancing machine.

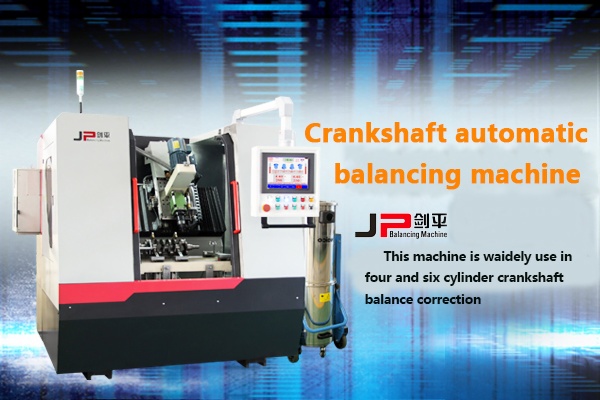

Crankshaft automatic balancing machine, so that crankshaft balance is no longer difficult.

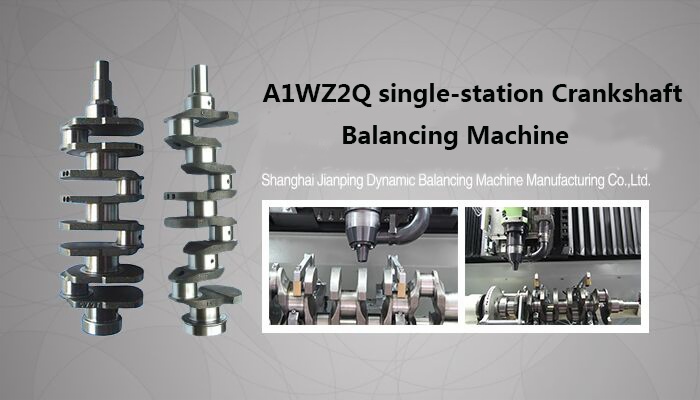

After analyzing the huge demand of the crankshaft in the automotive industry and the specific requirements of customers in the crankshaft industry, the relevant staff of Shanghai Jianping Dynamic Balancing Machine Manufacturing Co., Ltd. researched and developed

crankshaft fully automatic balancing machine with the advanced balancing technology of Jianping.

Jianping Crankshaft balancing machine using a professional electric measuring system can be widely used in automobile four-cylinder crankshaft crankshaft and six-cylinder dynamic balance correction, automatic balancing equipment to better meet customer demand for mass production.

Crankshaft as an important key component in the car engine, crankshaft balancing standards directly affect the performance of the engine. With the rapid development of China's automobile industry, the demand for crankshafts has also risen sharply. Therefore, crankshaft mass balancing and crankshaft balancing are of great importance to the quality and efficiency of crankshaft balancing. In particular, crankshaft balancing machines have received special attention The major manufacturers of high concern.

.png)

.png)

.png)