Flywheels, disk-shaped parts with a large moment of inertia act like an energy storage device. For a four-stroke engine, every four piston stroke work once, that is, only work stroke work, and exhaust, intake and compression of the three trips have to work hard. Therefore, the output torque of the crankshaft changes cyclically, and the crankshaft speed is also unstable. In order to improve this situation, the flywheel is attached to the rear of the crankshaft.

Unbalanced flywheel reason?

1, flywheel rotation, the clutch in the separation and combination of instantaneous and flywheel plane exist speed difference, causing the two relative sliding, the flywheel work surface wear. Flywheel plane will also be due to high-speed friction and heat generated by local ablation junction hard. The company is located in:

2, flywheel rotation, due to bear a larger torque, and often accompanied by the impact of the transmission torque load, for a long time the flywheel screw holes will have damage and deformation. The company is located in:

3, Friction plate wear thinning, rivet head beyond the friction plane, the flywheel face scratches or grooves, or friction piece damage, rivet loose, causing flywheel plane damage. The company is located in:

4, improper driving, or no free travel, or lack of pressure on the clutch plate, the clutch and the flywheel are often in the semi-clutch state, play the flywheel contact surface wear and tear.

Both the crankshaft and the flywheel are mass rotors. Without dynamic balancing, the centrifugal force often generated during rotation can cause engine idling jitters and vibration during high-speed operation, accelerating bearing wear. Manufacturers in the engine factory crankshaft and flywheel are balanced, in order to maintain the balance between the two in the design of the crankshaft interface plate and the flywheel connection, the general positioning pin positioning or connecting bolt holes arranged asymmetric, and some use Bolt diameter of the different methods to prevent disassembly after disassembly when the loss of dynamic equilibrium situation.

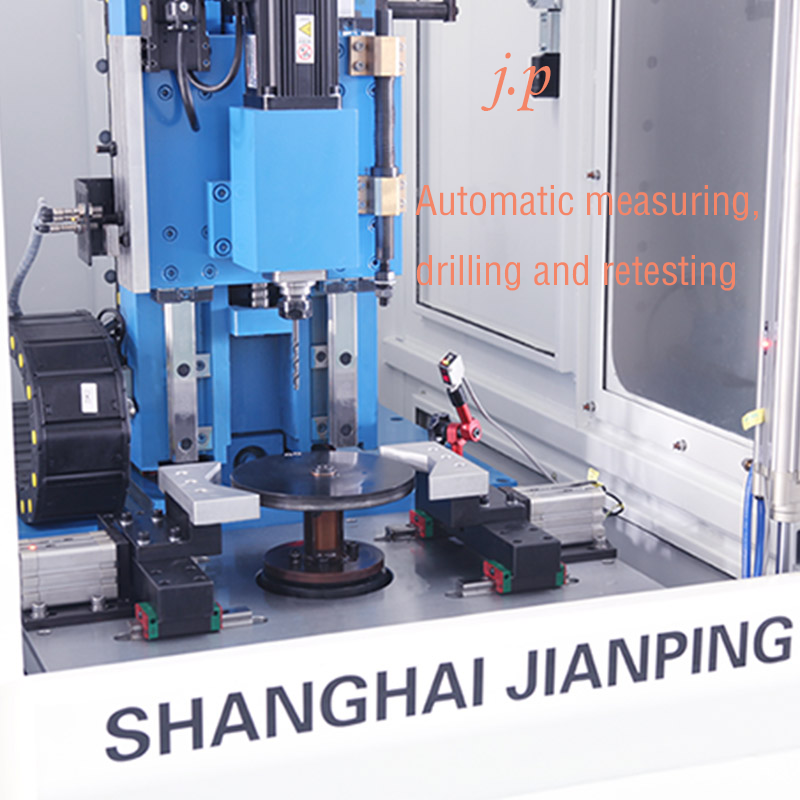

Sword level flywheel balancing machine, offers manual, semi-automatic or fully automatic operation, it provides a high degree of flexibility, good ergonomics and further improve the accuracy of the perfect combination to provide efficient daily work. The requirements may change in a few years. Combined with vertical or horizontal alignment module for drilling, riveting, welding or punching, all major calibration methods are provided. The ergonomics of all components have been optimized for the special programs used in the balance. Simple operation, clear structure, even if occasionally balance the child's play. There has also been a technical change: the foundation consists of proven mineral castings. This suppresses vibrations significantly better than gray cast iron and, together with vibration-optimized measurement techniques, forms the basis for a significant improvement in accuracy. With a fully adjustable speed adjustment, the available weight range is significantly extended, allowing the smaller rotor to be perfectly balanced.

.png)

.png)

.png)