Mechanical automation really merged as the modern Western industrial revolution should be. When the Watt improved steam engine to use a number of mechanical automatic control system: centrifugal governor and throttle and so on. Centrifugal governor has created a new milestone in mechanical automatic control.

The realization of mechanical automation will lead the machinery production to a new field, through the automatic control system, truly reached the large industrial production and reduced labor intensity, improved efficiency, so that the world's production involve to a brand new generation. Thus extended out of the electrical automation, the current industry has been inseparable from the automation system.

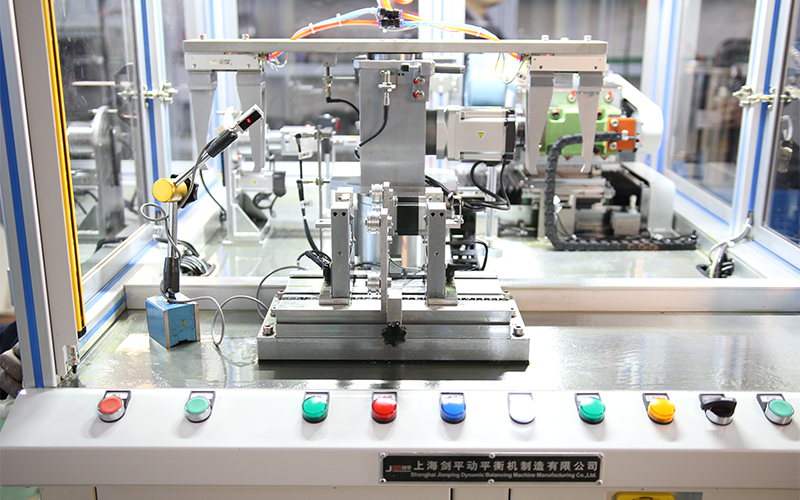

On the automation of balancing machines

An unbalanced rotor produces a pressure on its support structure and the rotor itself causes vibration during rotation. Therefore, in order to improve the quality of the rotor and its constituent products, reduce noise, reduce vibration, improve the service life of bearing parts (bearings), reduce the user's discomfort, reduce product power consumption, the rotor has to achieve dynamic balance test. Automatic balancing machine is the rotor in the rotating state of the dynamic balance measurement, calculating the amount of unbalance and the implementation of calibration in the tolerable range.

High-precision automatic balancing machine is the high-precision measurement technology and high-precision de-weight technology. From the measurement technology principle points, dynamic balancing machine can be divided into soft support dynamic balancing machine and hard support dynamic balancing machine. Soft support dynamic balancing machine’s supporting has low stiffness. The sensor measured with the amplitude is proportional to the unbalance. For the measurement of the type, hard support dynamic balancing machine support has high level of stiffness, the sensor measured with the centrifugal force would be proportional to the imbalance, Force type. As the hard support dynamic balancing machine has advantage of one time calibration and versatility. In recent years, it has become the main balancing machines.

.png)

.png)

.png)