Automation Process Flow In Dynamic Balancing Machines

Article Source: Jp Balancing Machine

Time:2017-06-19

Dynamic balance is a basic common problem in the rotating product and manufacturing process that must be resolved. Its advantages and disadvantages directly determine the performance of the product. In automotive, Industrial tools, or other industries, high-speed and light motor products’ requirements in vibration, noise and other performance are stricter. The corresponding motor rotor dynamic balance technology also made extremely strict about precision. Most of the plants are still using manual balancing machine. Weight removal needs to go 4 to 5 times. It does not generate only low production efficiency, poor calibration quality, but the damage to the rotor. The operator's experience caused the weight deviation of 10% to 50%.

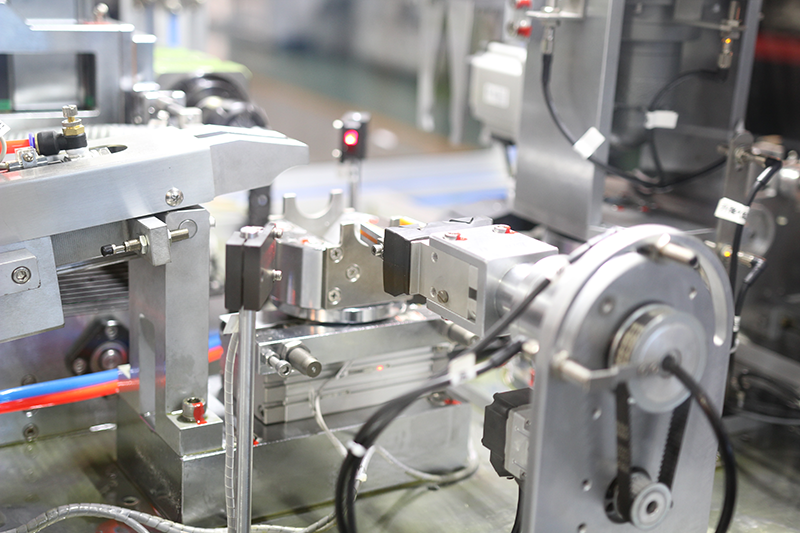

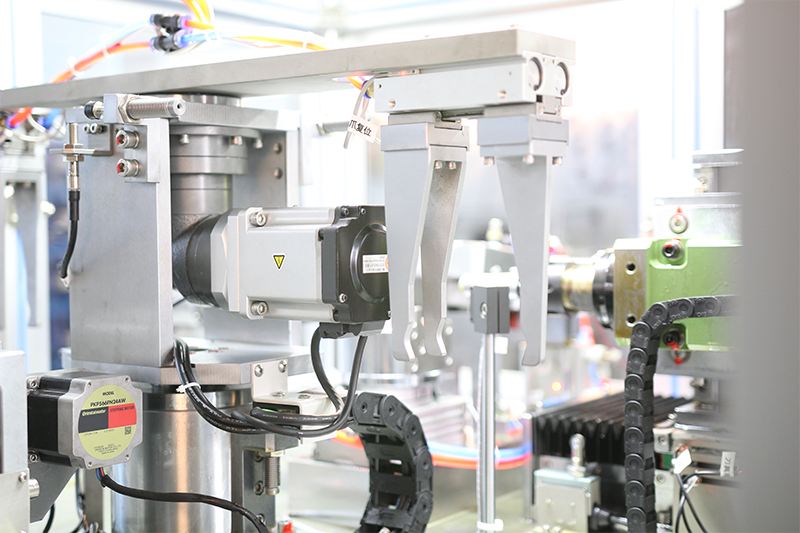

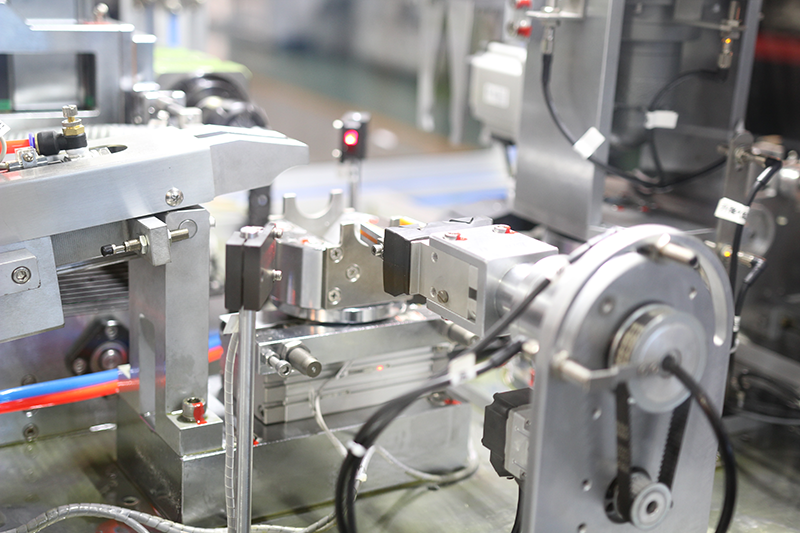

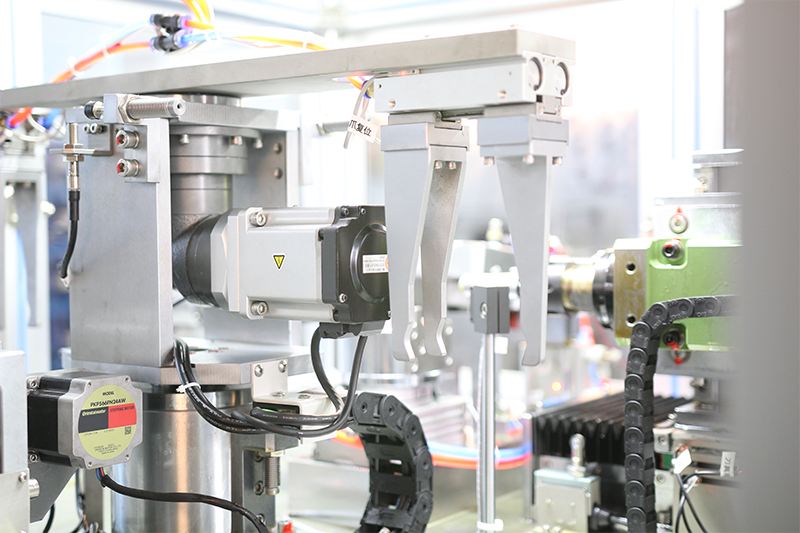

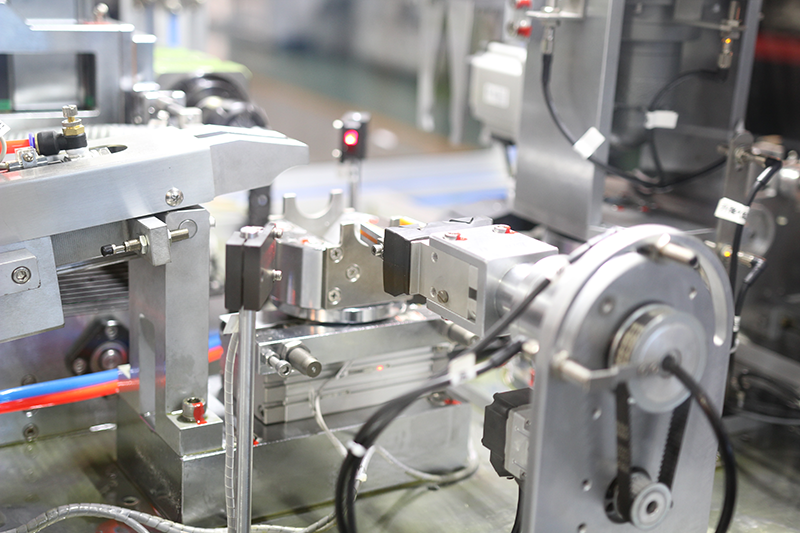

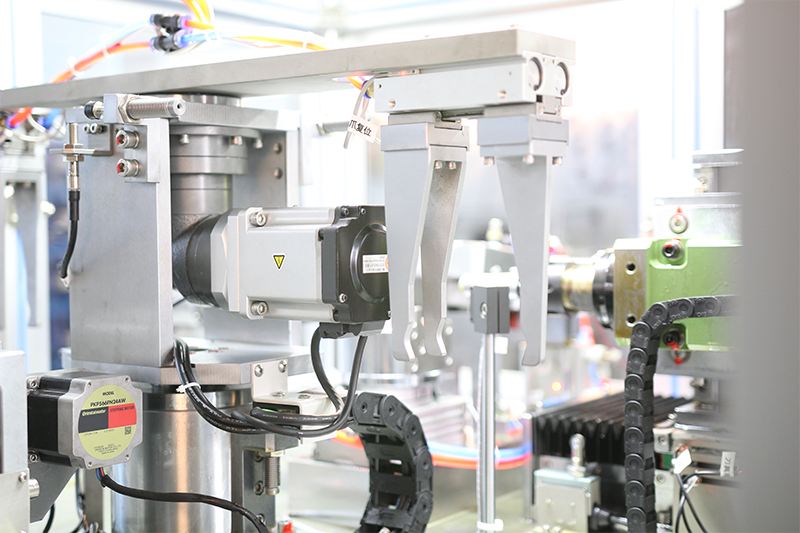

The two-station automatic balancing machine is composed of dynamic balance measurement, de-weighting two stations and manipulator transmission system and control system. The working process is: measuring and de-weight two-station parallel processing, measuring station task completion. The rotor has been sent to the de-weight station, while the milled rotor has been lift to measurement station for re-detection. The rotor transferring is charged by the robot transfer device. If the tested rotor is qualified, the machine cycle a new rotor. If it is not, then waste, refill with a new rotor.

Two-stage automatic balancing machine system works 1 cycle including the robot lift cylinder 4 times, the robot gripper reciprocating 2 times, the robot swing cylinder 1 times, positioning cylinder reciprocating 2 times, pressing the cylinder reciprocating 4 times, Gripper reciprocating 2 times, plus removal and turn action as a total of 28 beats. This is a multi-reciprocating pneumatic system controlling cycle.

The automatic balancing machine is a comprehensive high-tech integrating precision machinery with a variety of emerging technologies dominated by microelectronics, which is a complex technology of mechatronics. It is shown that the system can not only improve the dynamic balance accuracy of the rotor, to ensure product consistency and stability, but also improve the production efficiency and reduce the cost of a single product balance.