New Energy Motor Automatic Balancing Machines

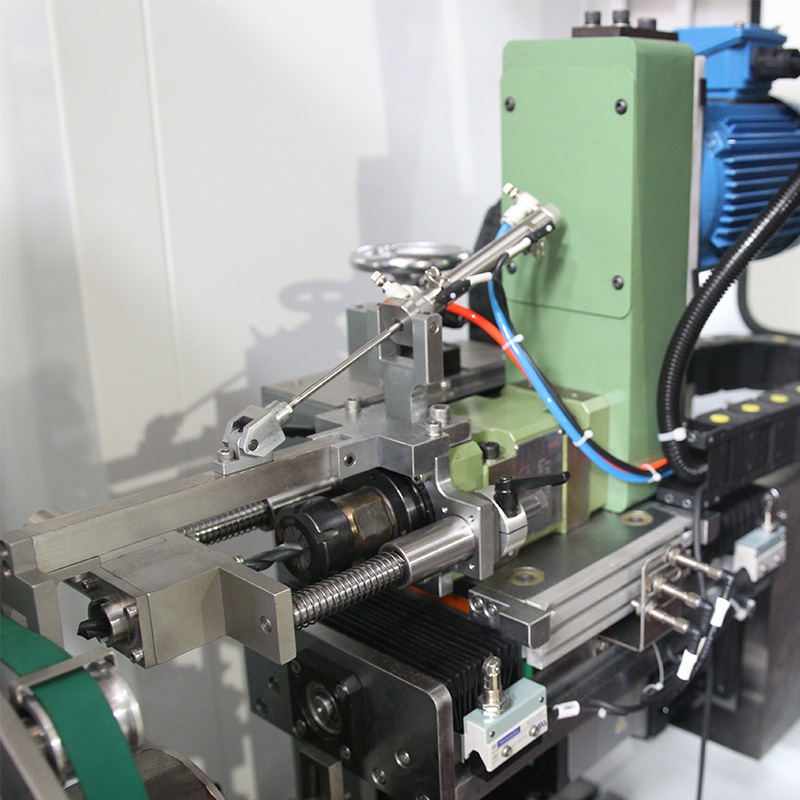

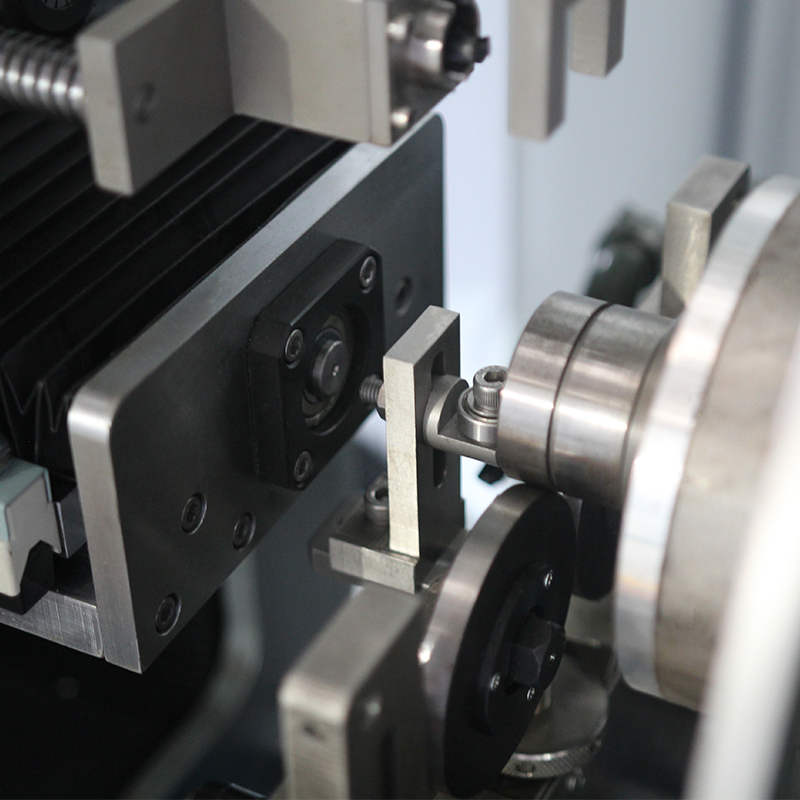

- Specially designed brackets transmit mechanical force with low vibration damping

- Durable and reliable sensor possesses good linearity

- Permanent calibration brings high accuracy with a permission of large initial unbalance amount

- Belt-driving offers higher precision and easier operation

- Advanced electrical measuring system and friendly man-machine interface

- Modular design offers a wide range of application

- Widely used for small and medium new energy motor, environmental protection motor, impeller, crankshaft, roller, shaft and any other rotating parts' balancing correction

- Technical Data

- Gallery

- Download

- Video

- Info Form

-

New Energy Motor Automatic Balancing MachinesTechnical data at a glance

A1WZ1 Weight:5-50kg Measuring System:Shanghai JianpingBearing Shaft Diameter:15-75mmDriven Measuring Motor:1.5kw Panasonic Servo MotorLamination Thickness:80-450mmDrilling Engaging Motor:0.75kw Panasonic Servo Motor Lamination Diameter:80-300mmDrilling Spindle Motor:0.75kwDeweight Diameter:60-280mm Cylinder:SMC Drilling Diameter:max 16mm Drilling Track:ShangYin Distance between Drilling Cutter and plane:10-150mmMain Driven Motor:Taiwan HankunMin Residual Unbalance Rate:<0.5g.mm/kgVacuum Cleaner:Suzhou Deico Unbalance Reduction Rate by One Time >95% Special rotor need to be confirmed with engineer

Processing period:150s (it will change accoring to weight.material.dimension)

.png)

.png)

.png)