WORK-LIFE BALANCE, THE MAGIC COMBINATION FOR PRODUCTIVITY AND QUALITY

Article Source: Jp Balancing Machine

Time:2018-05-02

WORK-LIFE BALANCE, the magic combination for productivity and quality

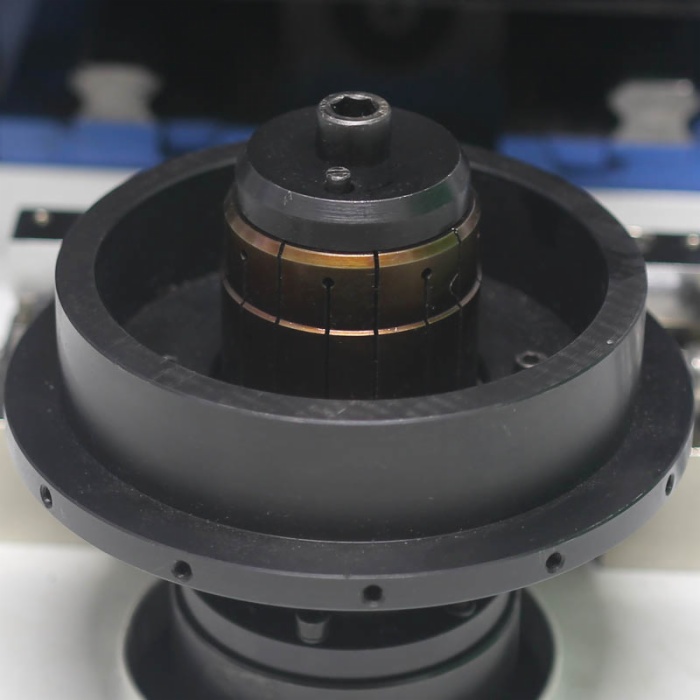

Innovative transmission designs require advanced manufacturing methods. Residual unbalance is a crucial topic as well as the volume production runs, especially considering the automotive landscape we are approaching.

Today’s automotive transmission world has changed and is rapidly evolving. Thanks to the latest solutions in the mainstream, including CVT and dual-clutch technologies, automatic vehicles are now much more efficient and often quicker than manual versions. Moreover, the electrification trend (EV) creates an additional pressing need for new transmissions designs. This re-engineering is aimed at installing an electric motor somewhere along the powertrain thus, as a positive consequence, today’s automatic cars are more attractive than they were two decades or more ago – even for those countries where typically the conventional gearstick covered the vast majority of vehicles.

This scenario creates new issues that engineers need to address. PARTS BALANCING, is one of these!

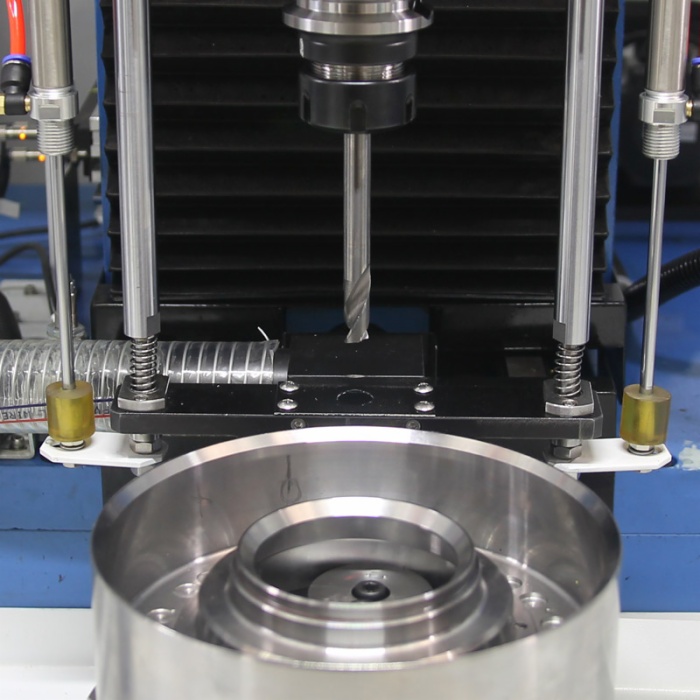

It is known that mass unbalance generates vibration which is a crucial factor for the powertrains. Low residual unbalance will improve both NVH and dependability of vehicles and automakers are aware of this benefit. Transmission layout must be also compacted as much as possible and, with this aim, the shape of the internal rotating components is often complex. These parts are typically balanced by removing weight through milling or drilling and variable surfaces (i.e. tapered, wavy etc.) are unfavourable factors for an accurate material removal.

The answer of Jp Balancing Machine is in the touch detection system between the cutter tool and the workpiece. We have our own PROPRIETARY solution thanks to the experience in the process control systems for grinding machines, where there is a large demand of these touch detection units.

This technical experience has been merged into the BALANCING MACHINES with the benefits of automatically compensating the tool wear and the part tolerance, guaranteeing high manufacturing accuracy and efficiency. The reliability of this process has made it possible to do this on every part!

Component cleanliness is also another essential factor. Lean Manufacturing frequently means optimizing the manufacturing processes upstream or downstream, while keeping the same quality standards. Preventing burrs and chips residual on the workpiece is another benefit that Jp Balancing Machine customers are experiencing.

The aforementioned “Touch-Detection” and “Zero-Chips” systems are features included in the standard scope of supply of our balancing machines.

.png)

.png)

.png)