In the simplest terms, static balancing is the process of addressing the unbalance of a component in a single plane only, as opposed to dynamic balancing which requires multi-plane correction. Static balance is at play when the centre of gravity of a unit is on the axis of rotation and there is no resulting centrifugal or “out of balance” force.

Why Static Balancing is essential

A static or vertical balancing machine can be used to detect the heaviest point of an unbalanced unit as it is rotated – assessing the accuracy of the balance. Next, applying the right counter-balancing weight to a suitable radius on the rotating body serves to move the centre of gravity to the centre of rotation. This removes the damaging stress upon the bearings of the unit – achieving a state of static balance.

The balancing of rotating bodies is absolutely essential if excessive vibration and unwanted stress are to be avoided. If left unaddressed, such forces can be unpleasant and noisy – causing irreparable and catastrophic damage in certain situations. Industrial machinery with unbalanced rotating masses will experience bearing failure alarmingly quickly which can be costly and time consuming to correct.

Static Balancing with Jp Balancing Machine

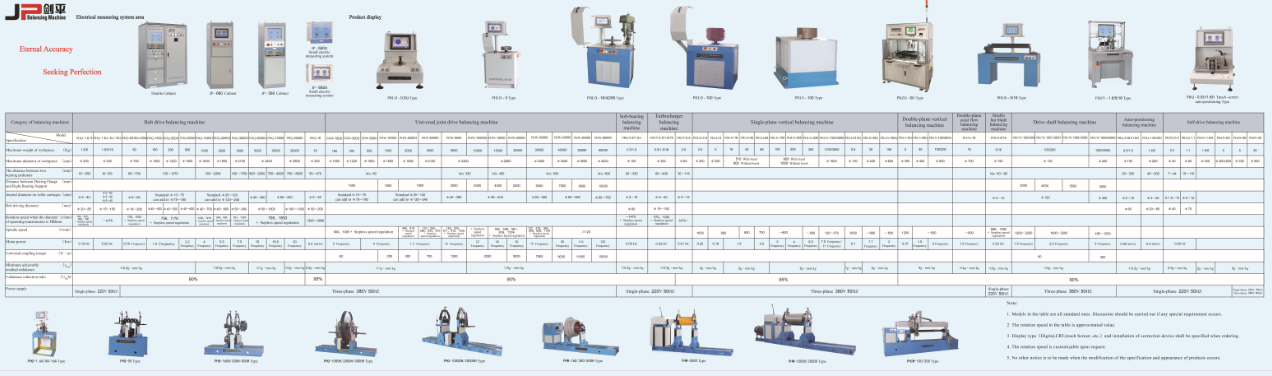

Our static or vertical balancing machines are suitable for rotors with a weight between 50g and 200kg, featuring manual or automatic correction systems as needed. From machines featuring vertical axis drilling correction to those specially designed for large rotors or tools and even a first class sub contract balancing service – Jp Baalncing Machine has the technology, modern expertise and experience that is the result of many, many years in the balancing industry.

If you would like to know more about static balancing machine, please get in touch with our team today or browse our range of static balancing machines here.

OUR PRODUCTS & SERVICES

.png)

.png)

.png)