Rotor in the production process, due to various factors (such as uneven material uneven porosity or shrinkage, parts weight error and machining errors, etc.) will cause imbalance .after the assembly, balancing machine is very necessary.Dynamic balance of the rotor is an extremely important process in the manufacturing process of the motor, which is directly related to the problem of whether the performance of the motor noise and the vibration index are up to standard

At present, the motor manufacturers use different specifications and models of dynamic balancing equipment. According to the measurement principle, there are hard bearing dynamic balancing machine and soft bearing dynamic balancing machine; according to the type of horizontal balancing machines and vertical balancing machines; according to the application, there are general and special balancing machines

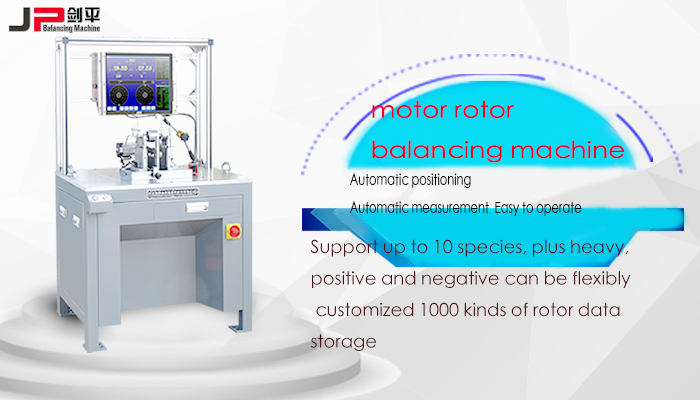

Auto positioning balancing machine can balance weighing up to 5 kg diameter of 260mm miniature motor rotor, which uses advanced servo drives, stepless speed parameters can be achieved, the smooth acceleration and deceleration, measurement stop automatically , it will stop in the Imbalance point automatically

Auto positioning rotor balancing machine using advanced electrical measurement system, the measured value display in the form of digital and vector combinations, all the system parameters are prompted, and the calibration process has a guide throughout, but also to establish monitoring Center, real-time monitoring of multiple balancing machine measurement conditions, to facilitate the management of data on the overall effective management

.png)

.png)

.png)