So what is dynamic balancing?

The ultimate goal of dynamic balancing is to reduce the dynamic unbalance of a rotor to zero, or otherwise to an acceptable level.

When vibration in two machinery shafts exists, a single plan or “static” correction will not be sufficient to address the unbalance at play.

Multi-plane unbalance is frequently a combination of both static and couple unbalance.

A dynamic balancing machine will be required to independently identify the type and level of unbalance located at each plane.

The unit which requires balancing will have both sets of bearings connected up to the sensors of a suitable balancing machine which will then detect the extent of the unbalance so that it can be corrected.

If static or single-plane balancing is performed on a unit that is experiencing unbalance in more than one plane, then the problem of vibration will still exist in operation – even if the unbalance appears to have been corrected on the balancing machine.

Two important points to remember when conducting dynamic balancing are to choose balancing planes that are as far apart as possible and to choose a balancing radius that is as large as possible – this will help you to achieve balance as effortlessly as possible.

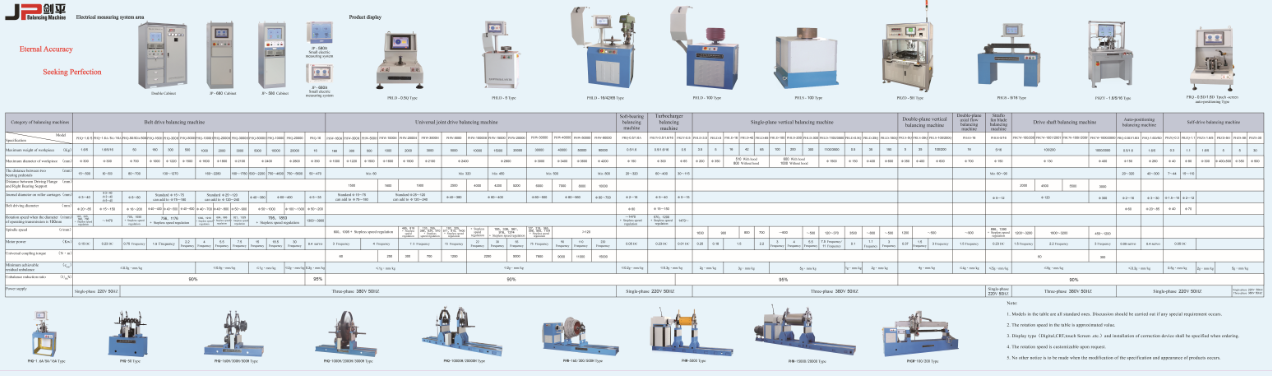

Dynamic Balancing machines and services

Due to advanced technology and modern expertise in the field of balancing, machinery is now running more efficiently and smoothly than ever before.

If you believe that you have a tricky part that needs to be dynamically balanced then pick up the phone and call us today on 00862139972151. The team at JP Balancing Machine have unrivalled experience in all areas of balancing and will be delighted help you with any requirement.

From machine upgrades and calibration to condition and vibration monitoring – our dynamic balancing service is second to none because we have the expertise and the professionalism to fully understand the needs of each and every customer.

.png)

.png)

.png)