Flywheel, Part of engine balancing

Article Source: Jp Balancing Machine

Time:2017-08-07

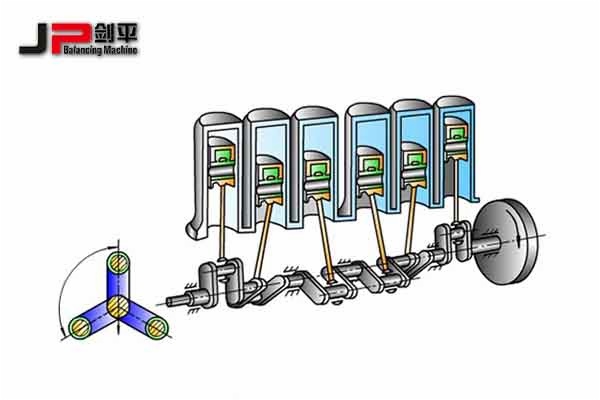

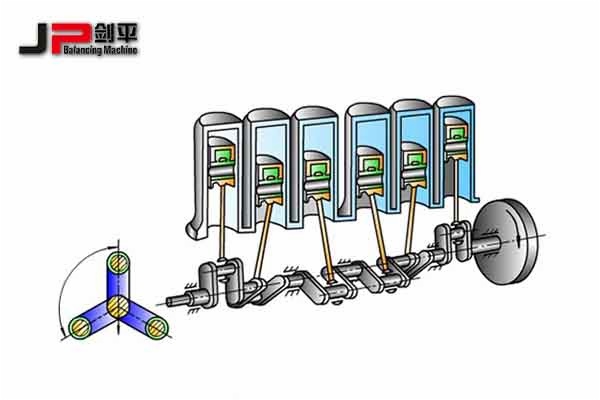

Flywheel is a large-quality cast iron inertial disc, which stores energy, the supply of non-work stroke needs, driven by the whole link structure over the top and bottom point, to ensure that the engine crankshaft rotation inertia rotation uniformity and output Torque uniformity, by means of its own rotation of the inertial force, to help overcome the start of the cylinder in the compression resistance and maintain short-term overload when the engine continues to run. Multi-cylinder engine flywheel should be with the crankshaft with the dynamic balance, or in the rotation due to the quality of the imbalance caused by the centrifugal force will cause the engine vibration, and accelerate the wear and tear of the main bearing. In order to disassemble without disrupting their equilibrium state, there should be a strict relative position between the flywheel and the crankshaft, with a locating pin or an asymmetrical arrangement of bolts. Flywheel common damage parts are ring wear damage, face ablation, deflection deformation and flywheel screw damage. Flywheel assembly is an important part of the engine, its operation up to hundreds of turns per minute, its importance can be seen.

Introduction of flywheel balancing machines

The machine is widely used in automobile clutch pressure plate, flywheel, pulley, pump impeller balance correction. The machine adopts the latest technology of JP Balancing Machines, parts from the balance measurement, angle positioning, drilling to heavy and re-test, all the implementation of automation; with simple operation, easy to use, high precision; for small and medium production.

.png)

.png)

.png)