Rotors are either classified as rigid or flexible. A rigid rotor is one whose service speed when in operation is less than 50% of its first critical speed. The critical speed is the theoretical speed at that causes the object to resonate, which dramatically increases system vibration. Above this speed, the rotor is said to be flexible.

JP Balancing Machine utilizes a hard bearing Balancing Machine Model PHQ-3000H with the following capacities;

Maximum Rotor Weight: 3000 kgs

Maximum Rotor Diameter: 2600mm

Rotor Shaft Diameters: 15mm to 240mm

Minimum Journal Centre Line: 170mm

Maximum Journal Centre Line: 4700mm

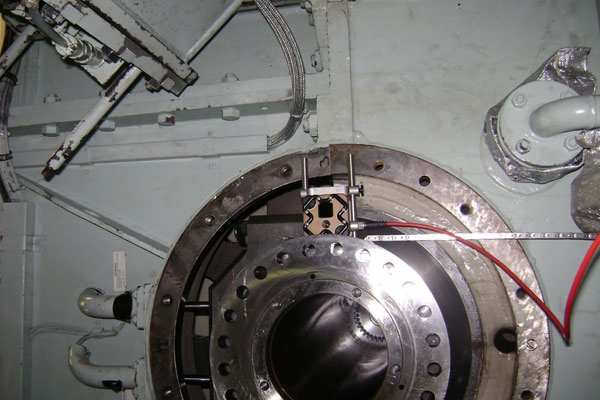

Dynamic Balancing is a process by which a rotor is supported on bearings encased in wheels and rotated about its axis at speed generally less than its service (operational) speed.

In doing so any out of balance forces are measured and recorded. The resultant out of balance forces are corrected by the addition or removal of weight, the position and amount of which is determined and indicated by the machine’s in-built computer.

Rotors are essentially rotating parts of machines and typical examples are;

Fans

Pump Impellers

Turbine Rotors

Compressor Rotors

Turbocharger Rotors

Shafts

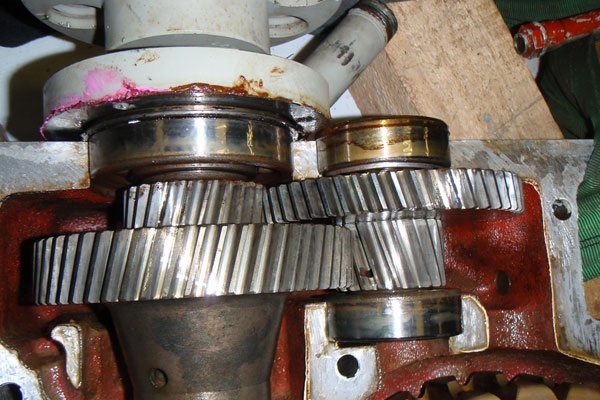

High Speed pulleys and gears

Flywheels

Discs

Armatures

.png)

.png)

.png)