Regular balancing machine operation, steps that give you a best rotating part

Article Source: Jp Balancing Machine

Time:2017-07-13

Vibration is a serious feature that will be considered as a significant liability in machinery development in modern machine design and construction. Rotating parts in industry should be taken dynamic balance, one of the efficiency method to weak the failure caused by mass uneven distribution in pouring.

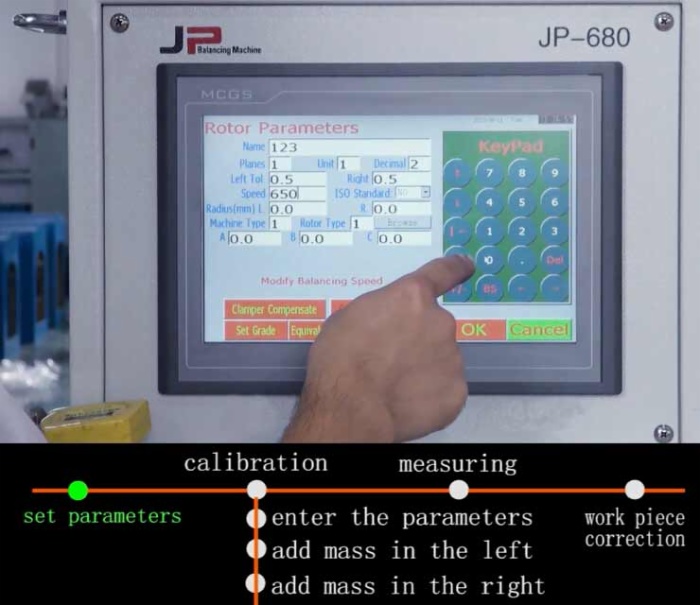

Dynamic unbalance is a combination of static unbalance point in the mass and the most of the unbalance is corrected by dynamic balance method and instruments. By machine there are steps rotating engineer should consider about since if all the contents your operation contain. You don’t have to doubted your rotating part will vibrated when been setup.

-

Mount the accelerometers and tachometer on the rotor plane. Sure about the sensor can see the probe sticker.

-

Pre-run the machine in a regular speed. Measuring the unbalance amount and do calibration for each plane by adding trail mass.

-

Mount correction mass at the positions indicate by the angles in system at the radius map.

-

Re-test the machine calibration rotor to ensure the amount of residual unbalance in the rotor.

After all the steps have been done, the following rotation parts queuing for test will be gained a consequence without bias and error.

.png)

.png)

.png)