According to data records, the water pump impeller itself is generally made of cast iron, and the vanes on the water pump impeller play an important role. The shape and size of the water pump impeller are closely related to the performance of the water pump. The water pump impeller can generally be roughly divided into single-suction and double-suction, single-suction impellers absorb water on one side, double-suction impellers generally absorb water on both sides, and pump impeller types are basically divided into four types: channel type, vane type, spiral centrifugal type, whirl type. The impeller is the core part of the water pump, and the surface of the impeller needs to be smooth, so as to reduce the damage to the impeller caused by the friction of the water flow. However, when measuring the dynamic unbalance of the water pump impeller, it is also necessary to balance and correct the entire components together, because after the impeller is replaced, the balance point of the entire component will change accordingly, which is more important for high-speed pumps and multi-stage pumps.

Because of the importance of balancing, Shanghai Jianping has developed a wahter pump impeller automatic balancing machine for the water pump impeller industry, so how does this automatic balancing machine detect? In simple words, when detecting dynamic unbalance, put the impeller on and clamp it, the impeller rotates, and the equipment detects the unbalanced position, then you can make a mark according to the indicated angle, and then remove the impeller for grinding. Now it takes a lot of time and manpower to use ordinary manpower to grind the impeller. If semi-automatic equipment is used to correct it, it will not save much time. If you need to improve productivity and reduce manpower, you should choose Jianping water pump impeller automatic balancing machine, which can reduce your worry about these problems.

Application range of water pump impeller automatic balancing machine

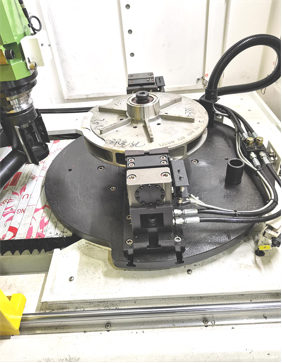

This fully automatic is mainly used in the unbalance correction of clutch pressure plate, pulley, water pump impeller, flywheel and other parts in the automotive field. This machine adopts the new technology developed by Shanghai Jianping, when testing workpiece, from unbalance measurement, angle detection, to drilling, milling and retest, the whole line implements an automatic production mode. This machine is simple in operation, saves manpower, easy to understand in software application, and has high precision, suitable for some small and medium-sized mass production manufacturers.

Shanghai Jianping Dynamic Balancing Machine Manufacturing Co., Ltd. has been accredited by CNAS, indicating that it has established a quality management system that meets international standards. The laboratory works strictly in accordance with the quality management system, and the technical ability of the laboratory can be guaranteed. The testing/calibration services provided by the laboratory can claim to meet the requirements of international standards. The competitiveness of the laboratory in the calibration/testing market has won the trust of government departments and all sectors of society.

.png)

.png)

.png)