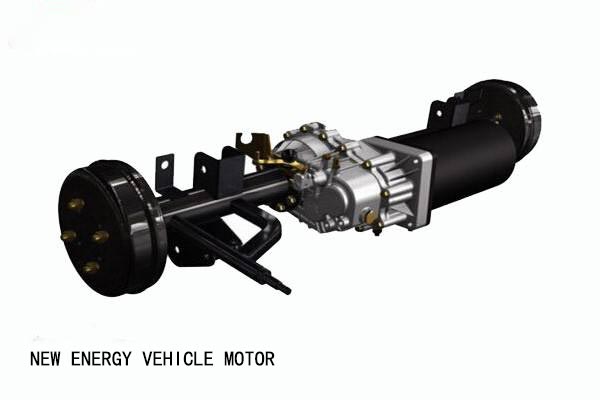

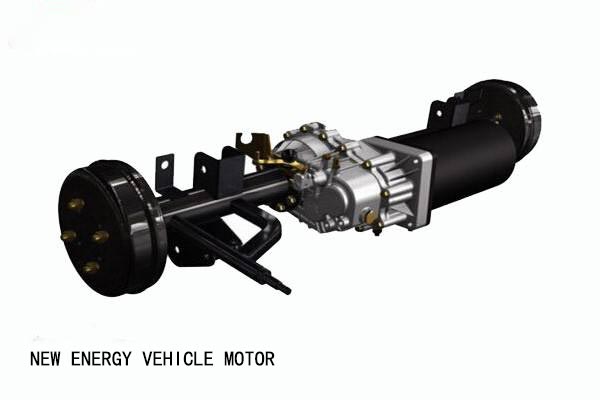

Compared with traditional pure fuel-efficient cars, new energy vehicles have higher requirements on the performance of motors, which are manifested in the following three aspects:

1. Wide range of speed regulation: There are two types of working conditions for new energy vehicles. When starting, accelerating, and climbing, it is required to work in the constant torque range; when driving at high speed, the motor is required to work in the constant power range;

2, the motor is required to work stably and has good seismic and heat dissipation performance;

3, lightweight, that is, the motor is small, to meet the requirements of vehicle lightweight

Therefore, in order to occupy a larger market in the field of new energy vehicles, it is necessary to have excellent motor technology. And a motor assembly consists of a variety of rotating workpieces, balancing of these workpieces is the basis of a high-performance motor. The balance of these rotating workpieces is inseparable from the detection of balancing machine

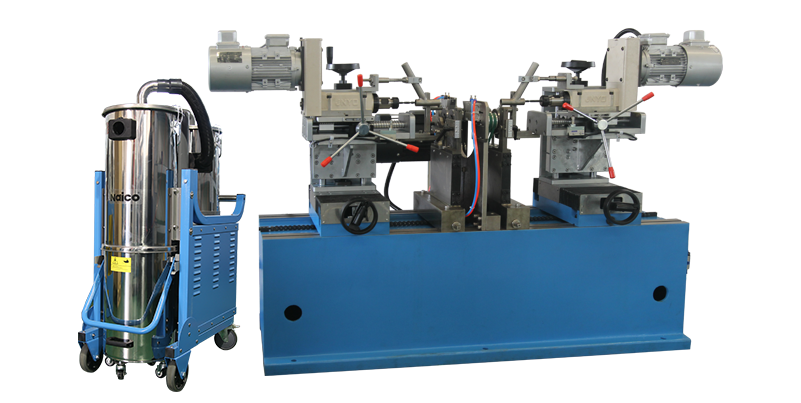

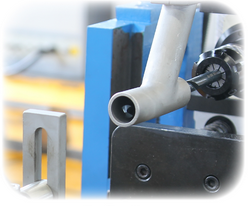

Jp New Energy Automotive Motor Balancer can provide you with a balancing solution for these rotating workpieces. It can detect various new energy motor rotors and shafts and other workpieces and automatically correct them. It adopts the belt drive and is driven by the variable frequency speed control motor, which can obtain the balance measurement with higher precision. After the test is corrected, the residual unbalance degree can reach ≤0.5g*mm/kg.

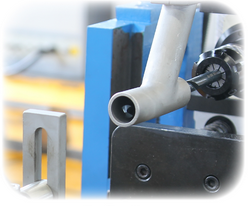

It is worth mentioning that the Jp New Energy Automobile Motor Balancer adopts the power head de-weighting device to cooperate with the function of starting and holding the workpiece, so that the workpiece can be removed without being removed directly on the machine, eliminating unnecessary steps during operation and improving the work efficiency

.png)

.png)

.png)