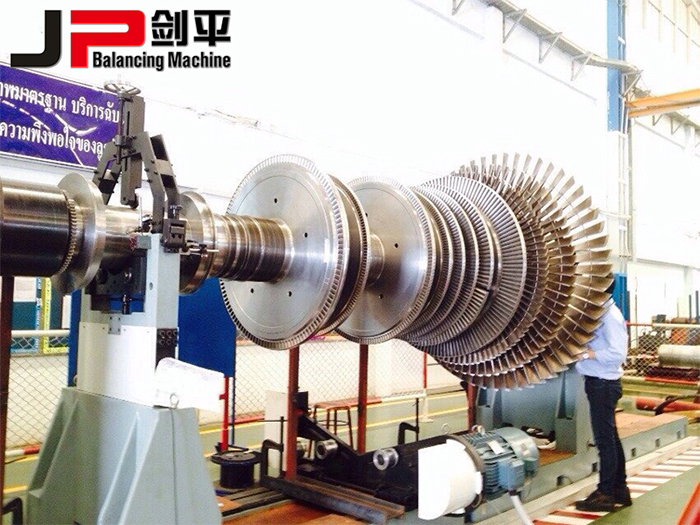

The Indonesian geothermal power plant had been experiencing some issues with one of its 60 MW steam turbines. During the previous two years, the pre-existing maintenance provider had repeatedly tried to repair the turbine, but the vibration issue had persisted. Despite several attempts to low speed balance the rotor at their premises, it still exhibited high vibration levels

Initial investigation

During one of these off-site balancing procedures, the plant engineers discovered deep cracks that were suspected to have been caused by a previous repair by another service company. As well-known experts in the repair of steam turbines, Jp balancing machine was called in to resolve the problem.

Repair re-evaluation

The initial plan was to machine out the material until the cracks were removed and then rebuild the shaft using submerged arc welding before machining it to nominal dimensions. However, after comprehensive inspection at Jp balancing machine, the crack propagation already had a spiral shape through the center of the shaft, making it impossible to machine out the crack area only. Jp balancing machine then came up with a repair proposal that involved designing a stub shaft that would be used to join the two pieces together before the shaft was rebuilt to its nominal dimensions.

Repair expertise

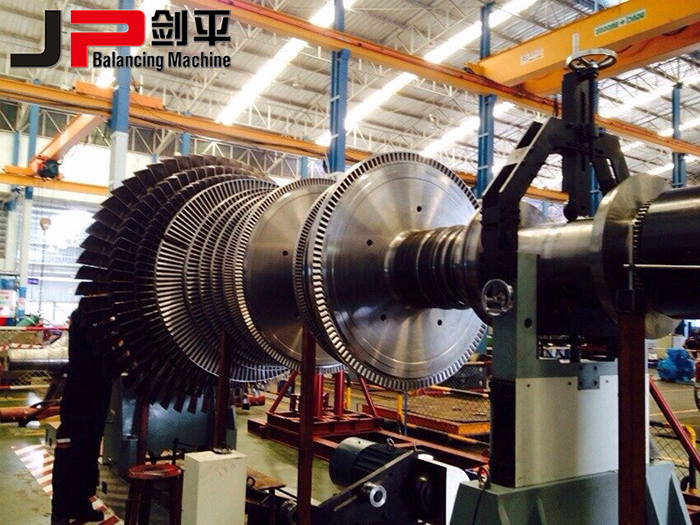

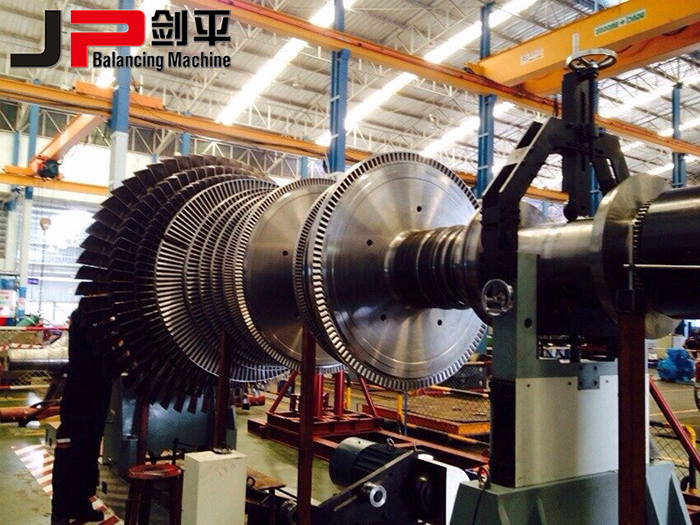

Joining two sections of a turbine rotor requires considerable expertise, including computer modelling and finite element analysis (FEA) to ensure that the proposed design would withstand the stresses of normal operation. The FEA was also carried out at an overspeed of 3’600 rpm to ensure that the centrifugal loading on the disks would not cause any damage to the rotor shaft after the repair. With all the necessary analyses completed, the machine shop started to prepare the two rotor shaft sections for the addition of the stub shaft.

Improving performance

While the repairs were being completed on the rotor, the field service team was working at the customer’s site to repair the diaphragm and improve the sealing of the casing. This work would be influential in improving the efficiency of the steam turbine.

Prior to the project being started by Jp balancing machine, the turbine required 393 tonnes of steam per hour to produce the 53.4 MW of energy. Despite one set of disks being removed, the repair to the static and rotor components of the turbine delivered by Jp balancing machine, enabled it to maintain an output of 55.1 MW but using only 374 tonnes per hour of steam, which is an 8% improvement in efficiency.

.png)

.png)

.png)