What We Concern More On Constructing Double Plane Vertical Balancing Machines

Article Source: Jp Balancing Machine

Time:2017-07-27

Fan rotors, which have uneven mass distribution, shape asymmetry, processing errors and other reasons that lead to the center of gravity off, will have greater vibration, heat and noise in rotation. According to the geometric characteristics of such rotors. The use of double-plane vertical balancing machine is more appropriate. In addition, hard bearing balancing machine has a simple structure, easy to operate, you can achieve permanent calibration and so on. Permanent calibration establishes the relationship between the electrical system and the mechanical system by appropriate scaling. It is possible to quickly and accurately measure the amount of unbalance on the selected correction plane. Various sizes and various shapes of rigid rotor in the model does not exceed the limits of the conditions. Without re-calibration, you can balance the same kind of work piece measurement.

Stiffness frame is one of the most important parts of the balancing machine, usually made of steel or cast iron. Since the amount of unbalance to be measured is very small, the vibration system is required to have sufficient sensitivity.

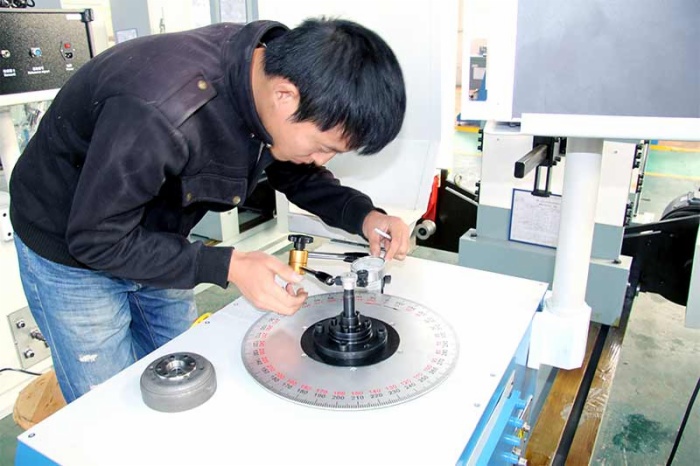

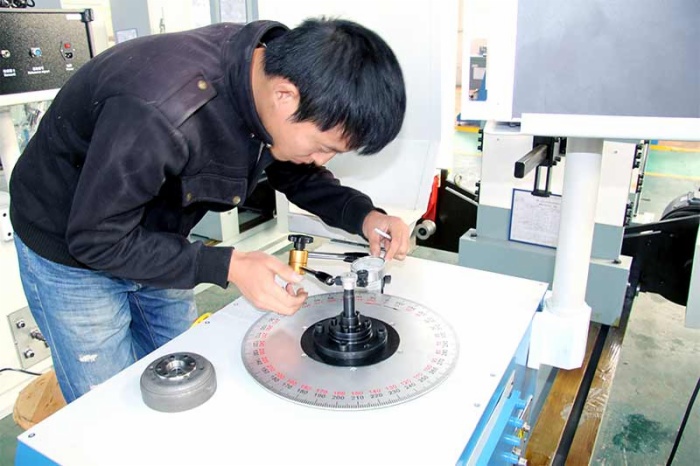

To ensure the accuracy of the balance, the quality of the fixture clamp have to be as small as possible. Such a rotor has a certain beat requirements. So the fixture clamp has to ensure that the rotor positioning is correct, easy assembly and disassembly, good repeatability. This machine clamp is the elastic pneumatic fixture. Without additional clamping force, the spindle can drive the rotor rotation.

The machine is consisted of base, rigid frame, spindle support, a horizontally mounted sensor, a vertically mounted sensor, AC servo motor, proximity switch, electric control part and measuring unit. Rigid frame installed in the base and the spindle support installed in the stiffness of the rack. The spindle bearing has a pair of high precision angular contacted ball bearings, axial is preload. When the bearings are assembled, spray a little oil. The two sensors are installed in the non-parametric part of the stiffness frame, and are connected with the vibrating body of the vibration measuring wire and the stiffness frame to receive the vibration signal. AC servo motor installed in the stiffness of the frame, due to the direction of vibration and stiffness in the direction perpendicular to each other, so the belt tension on the vibration measurement has no effect. Motor through the motor spindle pulley, driven spindle rotation, which led to the work piece rotation. Spindle support is installed below the reference signal board, each rotation of a week to produce a pulse signal, received by the proximity switch, as a reference signal.