Adjustment of Components, Ensures The Operation

Article Source: Jp Balancing Machine

Time:2017-07-21

Dynamic balancing machine in the course of the movement will inevitably produce friction, and friction will cause the relevant parts changes among the size, shape and surface quality, resulting in wear and tear, increasing the gap between the relevant parts. When the gap exceeds the reasonable range, only by adjusting the gap to ensure the relative movement between the dynamic balancing machine parts can guarantee the accuracy.

1, Track precision adjustment

For ordinary mechanical equipment, the gap between the sliding guides rail is appropriate, usually with 0.03mm or 0.04mm thick feeler in the end of the site to insert the inspection, requiring the insertion depth should be less than 20mm. If the rail clearance is not appropriate, it must be adjusted in time.

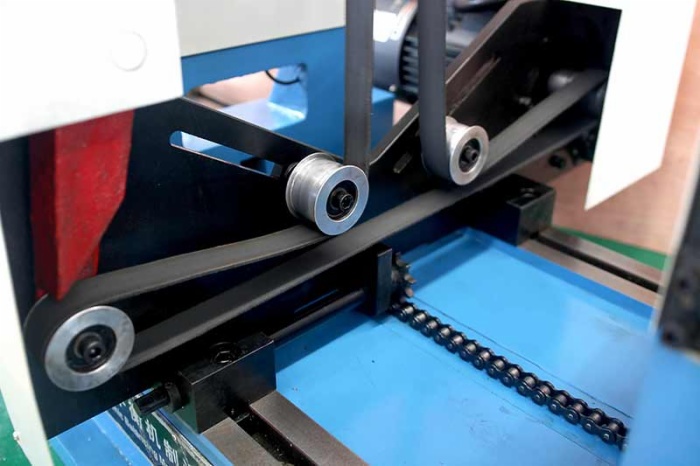

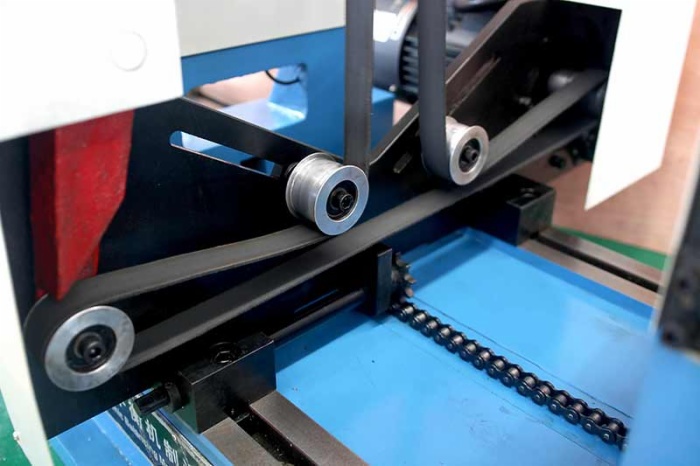

2, gap between the screw and nuts adjustment

The screw nuts drive of the screw lift is one of the most common mechanisms for achieving linear motion. Screws and nuts have very difficult to do without gaps. Especially after the use of a stage, due to wear, will increase the gap, affecting the normal work of the equipment. Therefore, in the equipment maintenance process, paying attention to eliminate the gap between the screw and nut is very necessary.

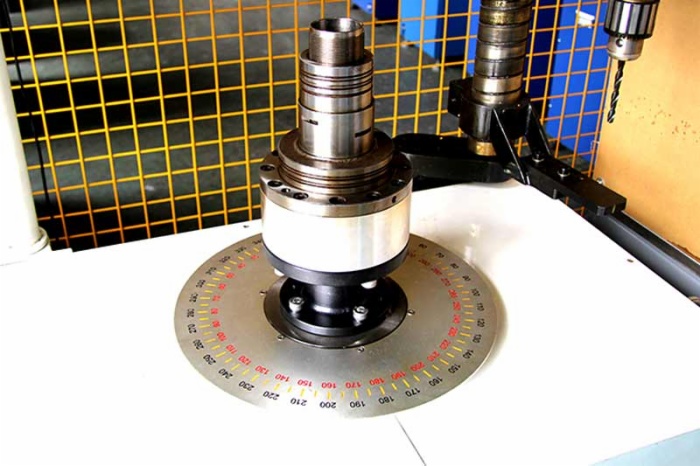

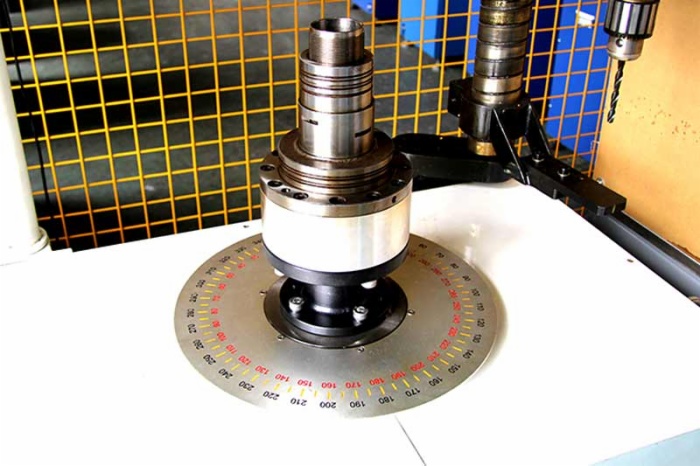

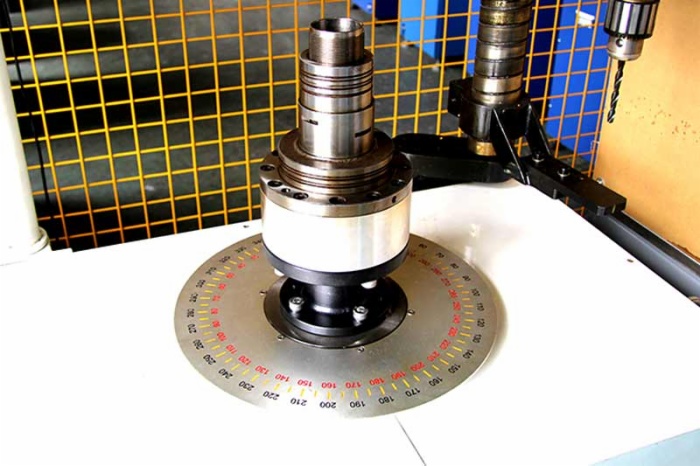

3, dynamic balancing machine spindle rotation accuracy adjustment

Balancing machine spindle rotation accuracy. In the spindle itself, the processing error in line with the requirements of the premise, in general, is largely determined by the bearings. Adjustment of the spindle rotation accuracy is the key to adjust the bearing clearance. Maintain a reasonable bearing clearance, the spindle components of the performance and bearing life is of great significance. Rolling bearings in the case of a larger gap will not only focus on the role of the force in the direction of the rolling body above, but also in the bearing. Outer ring raceway contact with a serious stress concentration, Shorten the bearing life and the spindle center line drift phenomenon, easily lead to vibration of the spindle components. Therefore, the adjustment of the rolling bearing must be preloaded, so that the bearing inside a certain amount of interference resulting in rolling and the inner and outer ring raceway will contact with a certain amount of elastic deformation in order to improve the rigidity of the bearing.