Leading balance-Centrifugal impeller dynamic balancing machine

Article Source: jp balancing machine

Time:2018-03-21

How to effectively complete the impeller dynamic balance correction?

Whether it is the use of thermal spray impeller, or the use of various methods of scaling the impeller, the effect will not be once and for all. After the long-term use of the induced draft fan, the vibration will still exceed the allowable upper limit value. At this time, the imbalance problem of the impeller can only be solved by dynamic balance correction.

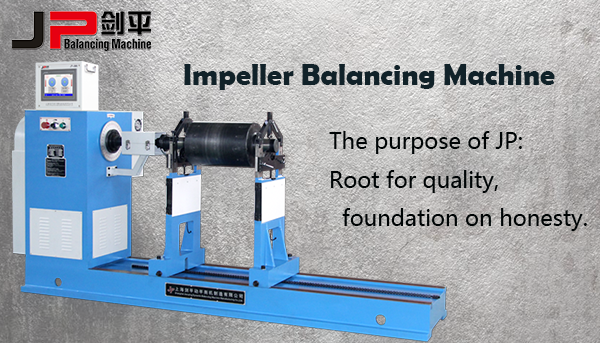

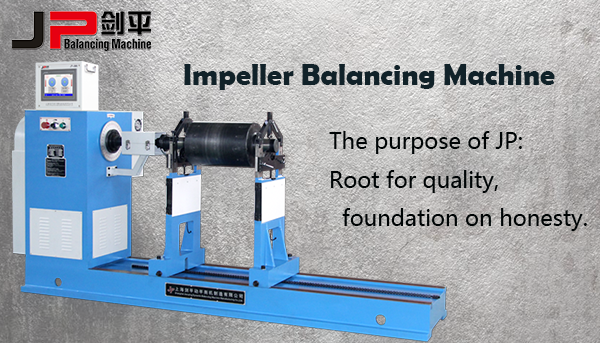

Centrifugal impeller dynamic balancing machine-Economic, practical and environmental protection

Centrifugal impeller balancing machine have a reliable design and use industry-leading measurement systems. Dynamic and static balance, supporting up to 10 kinds of support methods, add weight, forward and reverse can be flexibly customized, the measurement shows the balance of the amount and the angle unit can be customized, the display accuracy can also be customized to achieve real-time conversion unit to meet Different customer needs.

What is the purpose of balancing the impeller?

After the impeller passes the inspection, a single impeller dynamic balancing test is performed to check whether the material quality is uniform and manufacturing error, and the unbalanced amount is eliminated or reduced to the allowable range, making necessary preparation for the next step of the impeller overspeed test.

Jp balancing machine produces universal joint balancing machine can also balance rotors that weigh from 50 kilograms to a maximum of 30,000 kilograms and a diameter of 2800 millimeters. It adopts universal coupling or gear box transmission, which can obtain a variety of balanced speed or stepless speed regulation, and has the characteristics of large driving power, high precision, and easy operation. This machine is widely used in dynamic balance calibration of large and medium-sized rotors, blowers, centrifugal impellers, drying cylinders, and drums.